Various types of welding require different types of equipment. This is not to say that welding machines have specific jobs and cannot function in others, but every type of welding machine has a job that is considered a better fit than others. So, before purchasing a welding machine and letting sparks fly, you should consider what you need the machine for and which type would best serve you.

If you need a model that performs well in multiple situations, the MIG welding machine is an excellent pick. Here, we will help you figure out just how the MIG welders work. Their versatility allows them to be as suitable for welding thin sheet metal as it would be in welding heavy steel pipes. Better still, it is not very complicated to use, and even an amateur can perform admirably using the machine. An example of an easy-to-use MIG welder is the Forney Easy Weld 140MP, which is quick to start and simple to control, making it perfect for beginners.

That’s one of the significant advantages of the MIG welders. The machine is easy to use for both amateurs and experts. It’s as straightforward as pointing the welding gun to the material to be welded, pulling the trigger, and watching everything work. To achieve this level of ease, though, one would need to possess basic knowledge of the MIG welder, its parts, and how they all come together to make such an easy-to-use machine. However, in any welding, every detail of protection is important. So don’t forget to choose your best welding shoes.

Basics of MIG welding and all you need to know

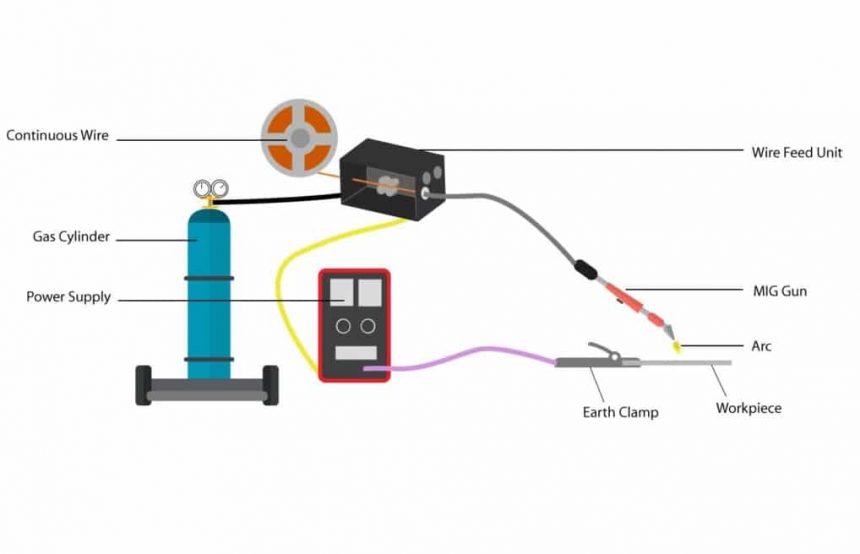

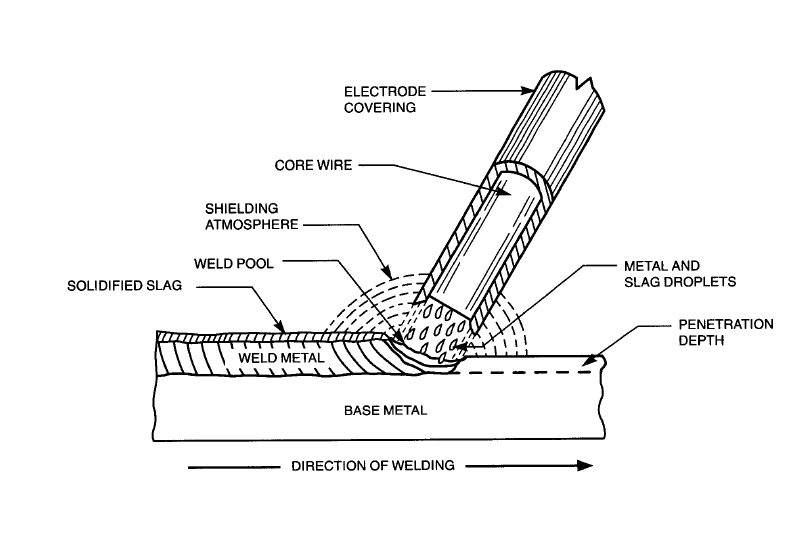

MIG welding is an arc welding process that utilizes a continuous solid wire that is heated and fed into a weld pool from a welding gun. This causes the two base materials to melt together and form a joint, which is the process’s goal. MIG stands for metal inert gas, and the method of welding is described as so because the welding gun that feeds the solid wire electrode also feeds a shielding gas along with the electrode. This gas is to help protect the weld pool from unwanted airborne contaminants.

Back then, the arc and the weld pool formed were protected by helium which was the first inert gas used as a shielding gas. Over time, though, argon also became very popular as a shielding gas, but CO2 was used as a shielding gas in the welding of carbon steel. However, due to the nature of CO2, any time CO2 or a CO2-argon mixture is used as a shielding gas, the process is referred to as metal active gas (MAG) processes instead.

The MIG welding makes use of an arc at the tip of the wire electrode. During the welding process, the wire electrode acts as both a heat source and a source of the welding joint’s filler metal. The arc located at the tip of the wire is required to melt along with the workpiece to create the weld pool.

The electrode itself is fed welding current via a copper contact tube. The weld pool is created as a result of the melting together of the arc, and the workpiece is protected by the shielding gas supplied through a nozzle surrounding the wire. The nature of the shielding gas depends on the type of metal being welded and the reason for the welding, but regardless, the function is the same; to protect the weld pool from contamination.

During the process, the wire used is continuously fed from a reel or spool powered by a motor drive. Continuous feeding is one of the reasons for the relatively high productivity of the process. The wire used may be solid or cored. While the solid wires are just simple drawn wires, the cored wires are composites made up of metal sheaths that may contain either powdered flux or metal filling within them.